- Drug Delivery

- Article

- Reading time: 12 min

Component by Component: The Inner Workings of a Wearable Drug Delivery Platform

In the world of wearable drug delivery systems, the seamless integration of sophisticated components is crucial for ensuring both functionality and patient safety.

The Swiss company Sonceboz, renowned for its expertise in motion control solutions, has developed an innovative platform for non-insulin drug applications. A key aspect of this platform is the disposable unit, which plays a central role in the device's operation. This unit was co-developed by Sonceboz and RAUMEDIC.

This article will provide you with a deep dive into the critical elements and components that make Sonceboz’s wearable drug delivery system a reliable tool in patient care. While the original design was provided by the customer, RAUMEDIC optimized the concept and adapted it for injection molding, leveraging expertise to further develop the product to its current level of maturity.

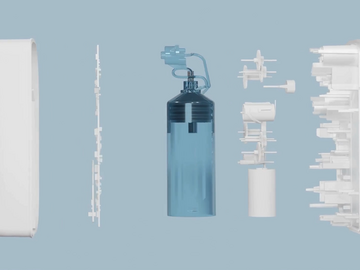

The Disposable Unit: The Core of the System

At the heart of Sonceboz’s device lies the disposable unit (colored blue in the video above), positioned centrally within the system. This unit is where RAUMEDIC’s expertise in fluid management and component integration truly shines.

The entire disposable unit is built upon a baseplate that houses all individual components. This baseplate serves as the foundation upon which the fluidic path and other essential elements of the disposable unit are mounted.

Fluidic Path and Pump Module

A key feature of the disposable unit is the fluidic path, a precisely engineered channel that ensures accurate medication delivery. The pump module is inserted directly into this path, facilitating the controlled flow of the drug.

2-C injection molding, including silicone parts.

- Small shot weight of less than 0,02g

- Overmolding

Overmolding

With chemical inert inner layer

We will circle back to the precise functionality of the different components of the fluidic path later.

For now, it is enough to remember that this assembly lies at the heart of the device – and is a highly critical component.

The Medication Journey – Part One: From Vial to Device

The operation of Sonceboz's device revolves around the precise movement of medication into and through various channels – and ito the patient, ensuring accurate dosing and patient safety.

Luer Connector

The Luer connector is a standard, commercially available component designed with a simple yet reliable principle. It securely connects a vial adapter, allowing the drug delivery device to be filled with medication. This flexible approach ensures that the device can be filled with the prescribed medication as needed, rather than being pre-filled.

Valve Piston Mechanics

Once the medication enters the device, it flows through a tube to the valve piston, a component developed with IP from Tith Sonceboz. The valve piston moves back and forth within the system, opening and closing different pathways as needed. It plays a crucial role in directing the medication into the appropriate channel when the pump cylinder is full

Reservoir Storage

The medication is temporarily stored in a reservoir within the device, where it remains until the system is fully loaded. The pump creates a vacuum that fills the reservoir, repeating the process until the vial is emptied and the reservoir is ready.

Final Preparation

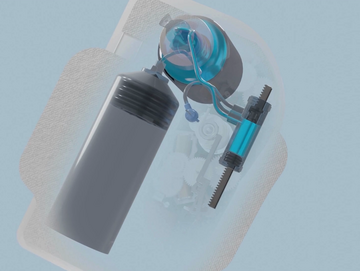

With the medication securely stored, the device is ready for use. At this stage, the pump is fully loaded and can be attached to the patient’s body.

The Medication Journey – Part Two: From Device to Patient

One of the standout features of this device is the use of a soft cannula for medication delivery, designed to maximize patient comfort.

Dual-Needle Insertion

The soft cannula is preloaded onto a steel needle. During insertion, both needles penetrate the skin simultaneously. The steel needle sets the soft cannula in place and is then retracted, leaving only the soft cannula in the patient’s skin. This ensures maximum comfort during the application process.

Medication Application

Once the soft cannula is in place, the actual drug delivery begins. The pump directs the medication from the reservoir, through the pump cylinder, and into the patient. The paths connecting the reservoir to the pump cylinder and the pump cylinder to the delivery needle are critical for accurate and efficient drug administration.

Precision in Dosing: The Pump and Valve Synergy as a Testament to Successful Collaboration between Sonceboz and RAUMEDIC

The synergy between the pump and valve units is what enables precise medication dosing. Sonceboz initially conceptualized the valve piston, with RAUMEDIC refining its final design. The valve’s sealing elements are engineered to ensure that no medication flows into the wrong channel, maintaining the system's integrity.

A Partnership in Innovation

Sonceboz’s wearable drug delivery device represents a significant advancement in medical technology. Each component, meticulously designed and integrated, plays a vital role in ensuring the device's efficacy and patient comfort. Through close collaboration with RAUMEDIC, Sonceboz has created a device that meets the highest standards and delivers medication in a safe and patient-friendly way.

The Fluidic Path: A Testament to RAUMEDIC’s Expertise

The fluidic path is a showcase of RAUMEDIC’s technological process, combining multiple advanced techniques to create numerous small but highly critical components:

- Injection Molding, including two-shot silicone injection molding.

- Overmolding: The steel needle is overmolded with specific parts, a technique that enhances durability and integration.

- Extrusion, including multi-layer extrusion of small tubing.

- Assembly & Post-Processing: The two-layer tubing, characterized by its small diameter, is expertly extruded and assembled. This includes the bonding of tubes, ultrasonic welding, and precise handling such as attaching the soft cannula to the steel needle.

More Than Manufacturer: How RAUMEDIC Designed and Developed the Disposable Unit

RAUMEDIC excels not only in manufacturing but also in the design and development of advanced medical devices. RAUMEDIC’s expertise spans from concept to serial production, utilizing a streamlined "Simple Six" process.

This methodology ensures that each step, from material selection to prototyping and final manufacturing, is optimized for quality, efficiency, and scalability.

If you want to learn more about this process, you can read about the six-step process in our collaboration with Sonceboz, here.

If you wish to contact RAUMEDIC in order to find out how we can help you, please contact us here.