- Drug Delivery

- Article

- Reading time: 8 min

From Concept to Reality: RAUMEDIC's Role in Developing Wearable Drug Delivery Systems

The field of wearable drug delivery devices has seen significant advancements in recent years, particularly in the management of chronic diseases. Novel devices offer patients greater autonomy, enhanced patient comfort, and increased chances of better therapeutic outcomes.

However, the development and manufacturing of such devices is complex – requiring a deep understanding of pharmaceutical technology, regulatory aspects, and – most of all - highly specialized expertise in manufacturing and processing technology.

RAUMEDIC, a leading player in the field of medical and pharmaceutical technology, has been at the forefront of providing specialized components for these novel and wearable drug delivery systems.

This article will explore how RAUMEDIC developed and manufactured key critical components for a wearable device: a patch pump - a small, wearable device that adheres to the skin and delivers medication.

The Challenge: Developing and Manufacturing the Heart of Sonceboz’ Innovative Platform Device

Sonceboz, a Swiss company known for its innovation in mechatronic solutions, developed an On Body Injector platform for non-insulin drug applications.

The goal was to create a wearable, disposable device that could enhance patient comfort and treatment efficacy. The company help pharmaceutical companies and partners deliver drugs at various speeds across various volumes and viscosities while providing safe and consistent drug delivery.

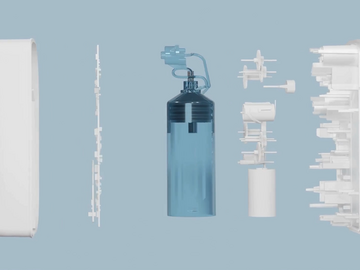

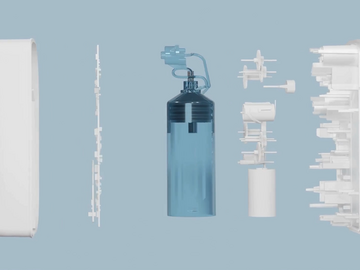

Key Components: Fluidic Path and Soft Cannula

Sonceboz aimed to develop a platform solution for a wearable patch pump, focusing on high-precision dosing to increase patient comfort and wearability.

Sonceboz also needed a partner capable of designing and manufacturing the heart piece of novel drug delivery devices: the fluidic path. This carefully designed channel directs the flow of medication, ensuring precise delivery and functionality. As this component is critical for the inner workings of modern drug delivery devices, it had to not only met stringent regulatory requirements, but also ensure seamless integration in the wearable device.

Soft Cannula

Fluidic Path

RAUMEDIC emerged as the ideal partner, offering comprehensive expertise in fluid management, micro-extrusion, needle handling, and silicone components such as septa and stoppers. These silicone elements are essential for the functionality of the assembly. Through a collaborative effort, RAUMEDIC and Sonceboz were able to develop a fully integrated needle insertion system and reservoir.

Let's take a look at how RAUMEDIC supported Sonceboz in enhancing their technology and optimizing the design process for their wearable pump solution.

The "Simple Six" Process: From Product Idea to Serial Production

RAUMEDIC's approach to product development is encapsulated in its "Simple Six" process, a six-step methodology designed to streamline the transition from concept to a fully-fledged serial product.

1. Product Idea

The first step was all about assessing the feasibility of the client's concept, which in this case involved a medication channel, the “fluid path” within a wearable device. RAUMEDIC's experts in product development and engineering collaborated to ensure the idea was technically viable, leveraging knowledge from previous projects.

The primary goal was to create a fluidic path, unifying various manufacturing techniques into a cohesive, single source offering while ensuring precise dosing and optimal product design.

2. Material Development

In the Material Development phase, RAUMEDIC selected and combined drug-compatible materials that minimized interaction with the medication, ensuring stability over prolonged storage. The focus was on identifying materials that were easy to process and integrate with other components, using technologies such as bonding or overmolding, to optimize the manufacturing process.

RAUMEDIC emphasized reducing the variety of materials used, aiming for simplicity and efficiency. For example, a two-layer tubing system was developed with an inert inner layer for drug compatibility and an outer layer optimized for further processing and assembly.

3. Product Concept

In the Product Concept phase, RAUMEDIC developed fully customized components tailored to ensure optimal drug efficacy. The design focused on minimizing dead volumes and residual medication in the fluidic path. Further, the design made sure to prevent the presence of air in the drug channel.

RAUMEDIC also developed a system for the secure integration of needles according to regulatory standards. Most importantly, the process was designed to be scalable, accommodating both small and large production volumes in the future.

4. Design & Prototyping

In the Design and Prototyping phase, RAUMEDIC transitioned from concept drawings to injection-molded designs, focusing on manufacturability and cost efficiency. Prototypes were rigorously tested, with optimizations made as necessary to ensure they met all requirements.

The transformation from prototype to serial-ready design (“Design for Manufacturing”) included developing scalable assembly processes and conducting essential tests, such as insertion and leakage and occlusion tests.

Components were designed to reduce complexity and the number of parts, streamlining production and ensuring consistent, high-quality manufacturing. This phase ensured that the final product was reliable, easy to produce, and met market demands with minimal risk of defects.

5. Manufacturing

In the manufacturing phase, RAUMEDIC has the capability to utilize its extensive technology and material expertise, including extrusion, thermoplastic and silicone injection molding, assembly, and needle handling, to produce high-quality components and subassemblies for Sonceboz's OBI.

By offering a full spectrum of capabilities, RAUMEDIC offers to benefit of reducing the number of suppliers needed by the customer, streamlining the sourcing process and centralizing responsibility. Insights from initial tests could be integrated into production, ensuring that all components are optimally aligned for functionality and quality. The secure connection of parts in the fluidic path, essential for accurate drug delivery and patient safety, can be meticulously managed.

6. Services

In the manufacturing phase, RAUMEDIC can leverage its extensive technology and material expertise, including extrusion, thermoplastic and silicone injection molding, assembly, and needle handling, to produce high-quality components and subassemblies for a patch pump.

RAUMEDIC: Drug Delivery Device Development Partner with a Unique Set of Capabilities

RAUMEDIC stands out as a unique partner in the field of medical and pharmaceutical technology, offering expertise across many critical areas of production: extrusion, thermoplastic and silicone injection molding, and assembly.

Unlike most other suppliers, RAUMEDIC provides a comprehensive, all-encompassing solution that integrates deep application knowledge, from needle insertion forces to specific application requirements.

This holistic approach not only streamlines processes but also offers valuable advisory support, enabling customers to benefit from RAUMEDIC's extensive experience and specialized know-how. RAUMEDIC’s ability to deliver a complete package, from concept to final product, ensures that customers receive unparalleled support and innovation at every stage of development.

Are you interested in finding out how RAUMEDIC can support your next project? Contact us here.